Blog

Digital Printing: Processes, Applications, and Advantages

- July 9, 2024

Digital Printing Process

Digital Printing Workflow

File Preparation

The process begins with preparing and formatting digital files, such as PDFs or desktop publishing files. These files must be properly formatted to ensure that the printer correctly interprets the colors, fonts, and layout.

Print Setup

Once the file is prepared, it is sent to the printer, which maps the image onto the chosen surface. The printer’s software controls the placement of the ink droplets, ensuring that the image is reproduced accurately.

Printing

During the printing process, minute droplets of ink transfer the image directly onto the media. This creates a high-quality print with precise detail and vibrant colors.

Types of Digital Printing

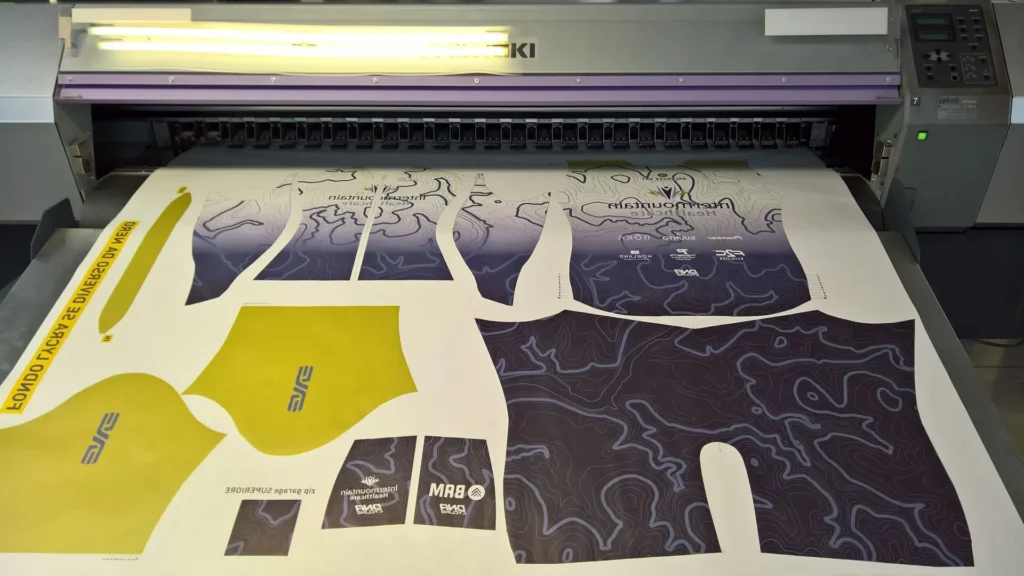

Inkjet Printing

Inkjet printing is versatile and suitable for a wide range of media. It is known for producing high-quality images with vivid colors. Inkjet printers are commonly used for printing photographs, posters, fine art prints, and industrial applications such as packaging and labeling.

Laser Printing

Laser printing is ideal for high-speed and high-volume printing. It is commonly used for printing documents, labels, and other materials that require sharp, precise text and images. Laser printers are often used in office environments for their reliability and efficiency.

Key Considerations

Digital Shirt Printing Methods

Direct-to-Garment (DTG)

This method directly prints the image onto the shirt using inkjet technology. It is ideal for small batches and customized designs. DTG printing allows for detailed, full-color images and is often used for printing custom t-shirts and other apparel.

Heat Transfer Printing

Using heat and pressure, this method transfers the image from a special paper onto the shirt. It is commonly used for mass production and promotional items. Heat transfer printing is suitable for creating designs with bright colors and complex graphics.

Advantages

Digital shirt printing offers high customization, quick turnaround, and vibrant colors. It allows for detailed and multi-color designs that are not easily achievable with traditional printing methods. Additionally, digital shirt printing is cost-effective for small to medium print runs, making it accessible to small businesses and individuals.

Types of Digital Printing Media

Digital printing can be performed on a wide variety of media, including paper, fabric, plastic, and more. The choice of media depends on the intended use of the printed material. For example, digital printing on fabric is commonly used for creating custom clothing and home textiles, while digital printing on paper is often used for marketing materials and office documents.

Digital printing is also used on specialty media, such as vinyl for banners and decals, and even on non-traditional surfaces like glass and metal. This versatility makes digital printing suitable for a wide range of applications, from promotional items to fine art prints.

Digital Printing and Design

Digital Printing Applications

Digital printing applications are diverse and versatile, spanning various industries. It is commonly used for creating marketing materials, such as brochures, business cards, and posters, due to its ability to produce high-quality prints quickly. Digital printing is employed for custom sportswear and textiles in the fashion industry, allowing for intricate and vibrant designs. Additionally, it is used in producing promotional items, packaging, and even fine art prints. Its flexibility and efficiency make digital printing suitable for both small-scale and large-scale projects, catering to personalized and on-demand printing needs.

Digital Printing on Fabric

Digital Printing Advantages

Efficiency

Digital printing offers faster setup and turnaround times than traditional printing. No plate creation is needed, which significantly reduces the preparation time.

Cost-Effectiveness

The reduced setup costs make digital printing particularly cost-effective for small to medium print runs. It is ideal for businesses and individuals needing smaller quantities of high-quality prints.

Customization

Digital printing allows for easy customization of prints for various applications. Each print can be tailored to meet specific requirements, making it a versatile option.

Environmental Impact

Digital printing generates less waste due to precise ink usage. It is considered a more environmentally friendly option compared to traditional printing methods.

Digital Printing Machines

Features

Brands and Models

Conclusion